How 3D Printing Is Revolutionizing Custom Sports Gear

Photo by Snapmaker 3D Printer on Unsplash

The Transformative Impact of 3D Printing on Custom Sports Gear

3D printing, or additive manufacturing, is rapidly reshaping the landscape of sports equipment. By allowing for the creation of custom, athlete-specific gear, this technology is driving performance, safety, and accessibility to new heights. The shift from mass-produced, one-size-fits-all products to personalized sporting solutions is now a reality, not just for elite professionals, but increasingly for everyday athletes as well.

[1]

Custom-Fit Equipment: Comfort, Safety, and Performance

Traditional sports gear often sacrifices comfort for protection or vice versa. Ill-fitting equipment can hinder performance, cause discomfort, or even contribute to injury. 3D printing changes this by enabling the fabrication of gear that is tailored precisely to each athlete’s body and needs:

-

Helmets:

Innovations such as the Riddell SpeedFlex Precision Diamond Helmet use advanced 3D-printed lattice liners, custom-fitted to an athlete’s head for unmatched impact absorption and comfort.

[2]

-

Mouthguards and Shin Guards:

Dental scanning and 3D modeling allow for mouthguards and pads that fit like a second skin, maximizing both protection and mobility.

[3]

-

Gloves and Racing Gear:

Paralympic athlete Arielle Rausin created custom racing gloves using a consumer 3D printer, reducing costs from $350 to just $4 per glove while improving comfort and efficiency.

[5]

To access custom-fit sports gear, athletes can consult with specialty sports equipment providers or explore collaboration with companies integrating 3D scanning and additive manufacturing capabilities. Some major brands offer online customization platforms, while others may require you to visit a certified fitting center for scanning and measurement.

Revolutionizing Footwear and Sportswear

Footwear giants are leveraging 3D printing to produce shoes and insoles tailored to each athlete’s unique biomechanics:

-

New Balance:

Collaborates with Formlabs to produce 3D-printed midsoles using proprietary photopolymers, offering enhanced responsiveness and fit.

[1]

-

Nike:

Uses 3D-printed plates in its Vapor Laser Talon football cleat and offers consumer customization through the Nike By You platform.

[1]

To benefit from these innovations, you can:

- Visit brand-specific customization sites (such as Nike By You or New Balance’s custom platforms) for bespoke options.

- Work with podiatrists or sports medicine specialists who partner with 3D printing labs for custom orthotics and insoles.

Always check with your preferred brand for current offerings, as availability and technology access may vary by region and product line.

Photo by Florian Schmetz on Unsplash

Next-Level Equipment Design: From Rackets to Bicycles

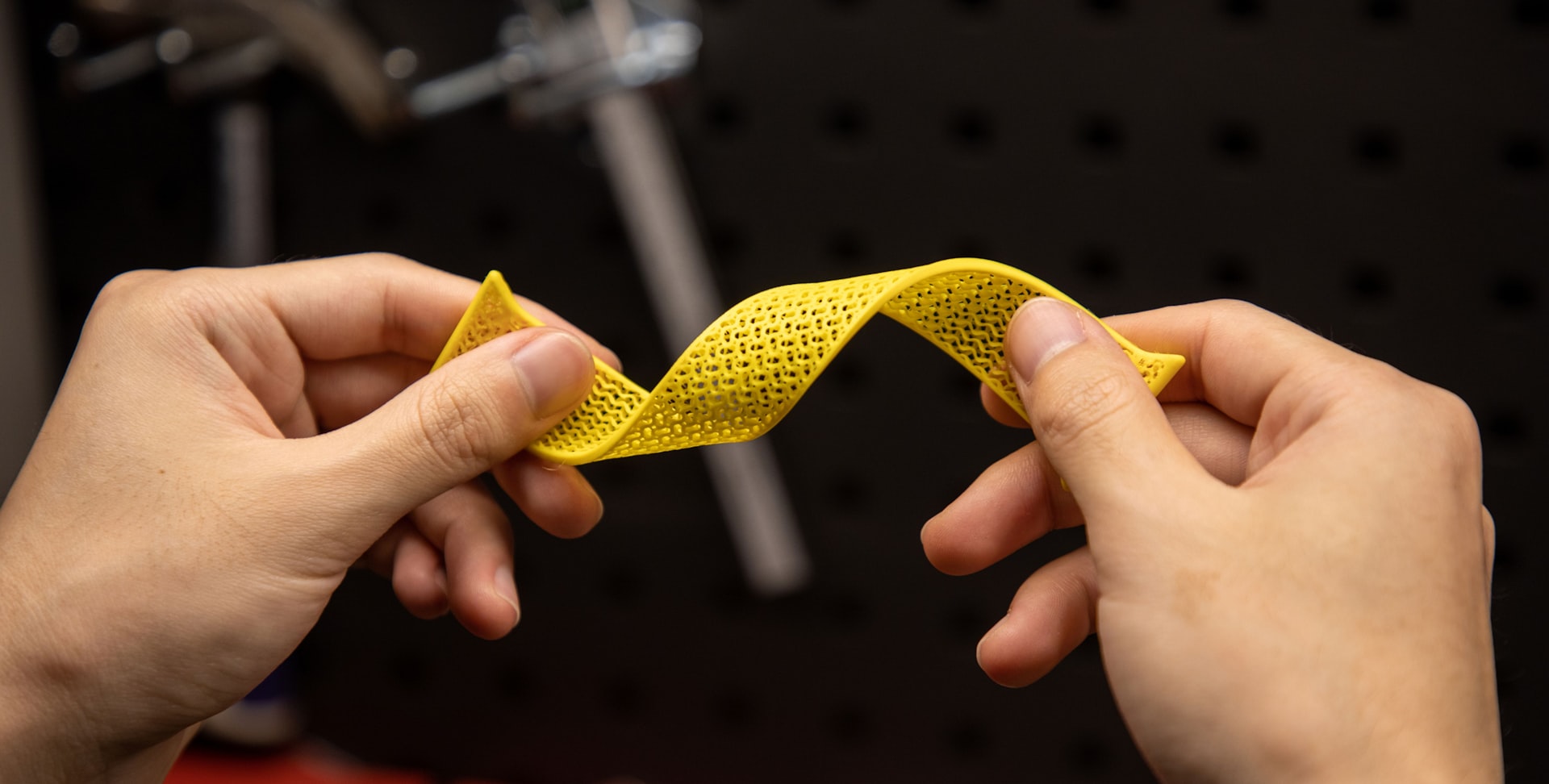

The flexibility of 3D printing allows manufacturers to experiment with new forms and materials, creating lighter, stronger, and more efficient equipment:

-

Wilson’s Airless Basketball:

This prototype, made possible by 3D printing, mimics the performance of a traditional ball without the need for inflation and features a unique lattice structure.

[2]

-

Cycling:

Custom 3D-printed bike frames deliver optimal weight and aerodynamics, tailored to each rider’s body and style.

[3]

-

Golf and Rackets:

Clubs, rackets, and grips can be modeled for individual preferences, enhancing control and precision.

[3]

To pursue custom sports equipment, consider contacting manufacturers directly or working with specialty sporting goods retailers. Some companies now offer digital scanning and design consultations, either in-store or through affiliated clinics. If you are an engineer or maker, open-source CAD files and 3D printing services can help you design your own gear, though professional guidance is recommended for safety-critical equipment.

Expanding Accessibility and Reducing Costs

3D printing can democratize access to custom sports gear. Previously, only elite athletes could afford tailor-made equipment, but additive manufacturing can significantly reduce production costs and lead times. For example, custom racing gloves that once cost hundreds of dollars to mold can now be made for a fraction of the price using desktop 3D printers.

[5]

Additionally, initiatives such as enlarged lacrosse stick heads for special needs players demonstrate how technology can be adapted for inclusivity and broader participation.

To take advantage of these opportunities, you can:

- Explore local makerspaces or university labs offering 3D printing access for community projects.

- Contact adaptive sports organizations or nonprofits, which may provide resources or collaborate with 3D printing partners for specialized gear.

- Search online for open-source communities sharing CAD files and modification guides for custom sports equipment.

If you are considering starting your own venture, research the regulatory requirements and safety standards applicable to sports equipment in your area to ensure legal compliance and user safety.

Challenges and Considerations

While the potential is vast, there are important challenges to consider:

- Material Limitations: Not all 3D printing materials are suitable for high-impact sports; users should verify materials meet safety standards.

- Certification: Certain sports leagues or organizations may have equipment approval processes; check with your governing body before using custom gear in official play.

- Access and Expertise: Advanced scanning and design may require professional assistance. Users should seek reputable providers and consult reviews or testimonials when selecting a service.

- Learning Curve: For DIY enthusiasts, acquiring CAD and printing skills can be rewarding but requires time and investment in training.

If you are unsure where to start, consider reaching out to sports medicine professionals, athletic trainers, or local universities with engineering departments for guidance and referrals.

Practical Steps for Accessing Custom 3D-Printed Sports Gear

- Identify Your Needs: Assess what gear you want to customize-shoes, helmets, protective pads, or equipment.

- Research Providers: Look for established sports brands or local sports equipment companies offering 3D scanning and printing services. Use search phrases like “custom 3D-printed [gear type] near me” or include your city for localized results.

- Get Scanned: Many providers require a digital scan of your body part or movement pattern. This can be done in-store, at a clinic, or sometimes using smartphone apps.

- Review Design Options: Work with the provider to specify materials, features, and customization options. Review prototypes or digital models before production.

- Order and Test: Place your order, then test the fit and function upon delivery. Provide feedback for further refinement if needed.

- Stay Informed: As technology evolves, new materials and services become available. Regularly check with your provider or major brands for updates and new offerings.

If you cannot find a suitable provider, consider contacting your national sports association or federation for recommendations, or seek advice from sports medicine clinics and physical therapists familiar with 3D-printed solutions.

Alternative Approaches and Future Outlook

For those without access to commercial 3D printing services, alternative approaches may include:

- Joining maker communities, where collaborative projects can help design and print custom gear.

- Partnering with educational institutions or innovation hubs offering access to 3D printers and expertise.

- Utilizing global online platforms to source custom designs or connect with designers who can assist with prototyping and production.

The future points toward greater personalization, improved safety, and widespread availability of custom sports gear. As additive manufacturing technologies mature, expect even more sophisticated materials, faster turnaround, and seamless integration of data-driven design into mainstream sports equipment.

References

- [1] ThomasNet (2023). How is 3D Printing Shaping Sports?

- [2] 3Dnatives (2023). The Top 3D Printing Applications in Sports.

- [3] 3DReality (2023). 3D Printing in Sports – From Custom Shoes to High Performance Equipment.

- [4] Dassault Systèmes (2023). 3D Printing in Sports.

- [5] University of Illinois (2017). 3D Printing: A Game Changer for Sporting Good Industry.